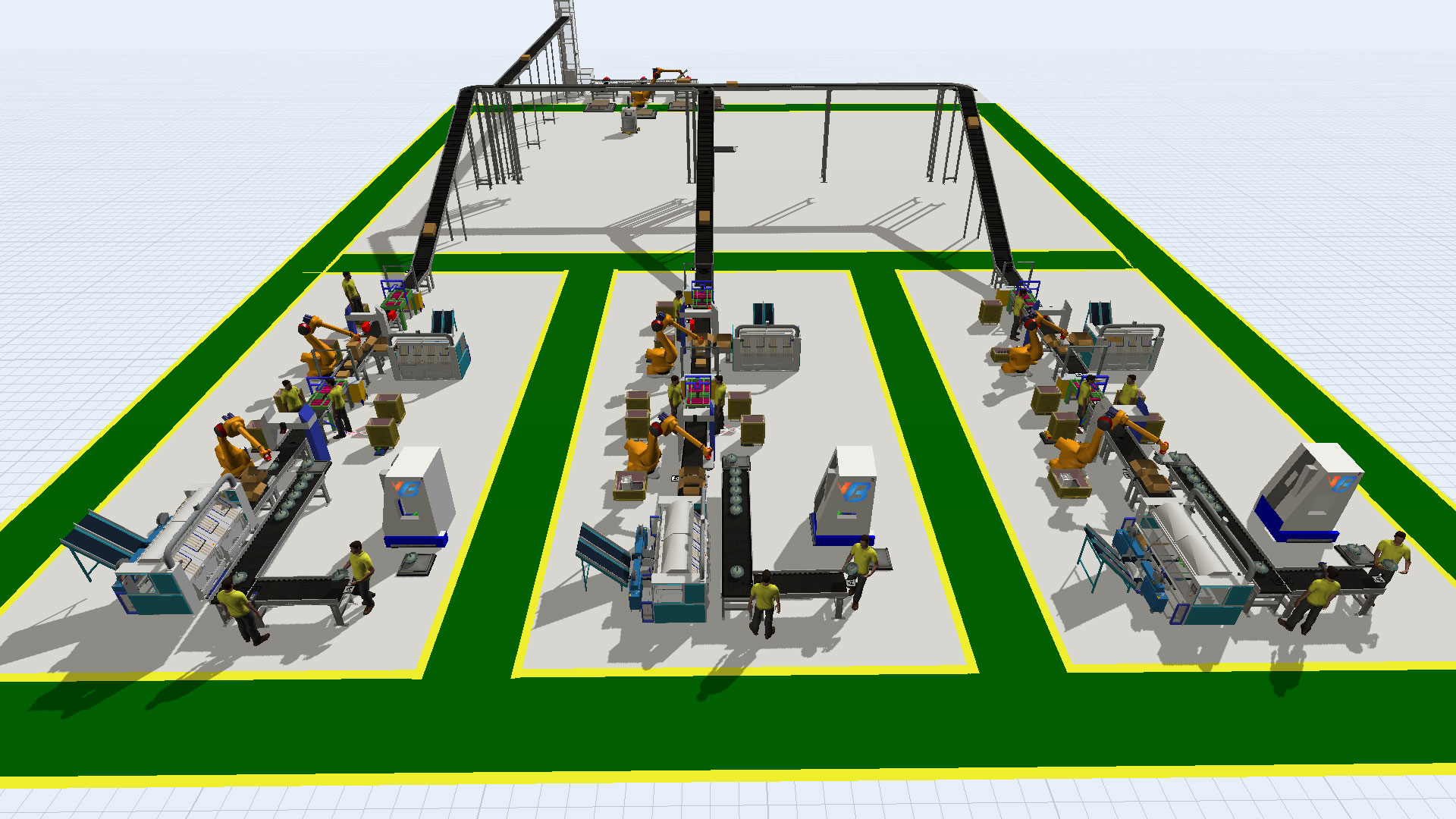

EMS Factory Layout Planning Services

Our EMS Factory Layout Planning Services optimize your manufacturing environment for efficiency and productivity. We analyze your operations and workflows to design layouts that facilitate smooth material flow, minimize bottlenecks, and enhance safety. Our team uses advanced planning techniques to create customized solutions tailored to your specific production needs, ensuring optimal use of space and resources. Trust us to help you establish a factory layout that maximizes operational efficiency and supports your growth objectives.

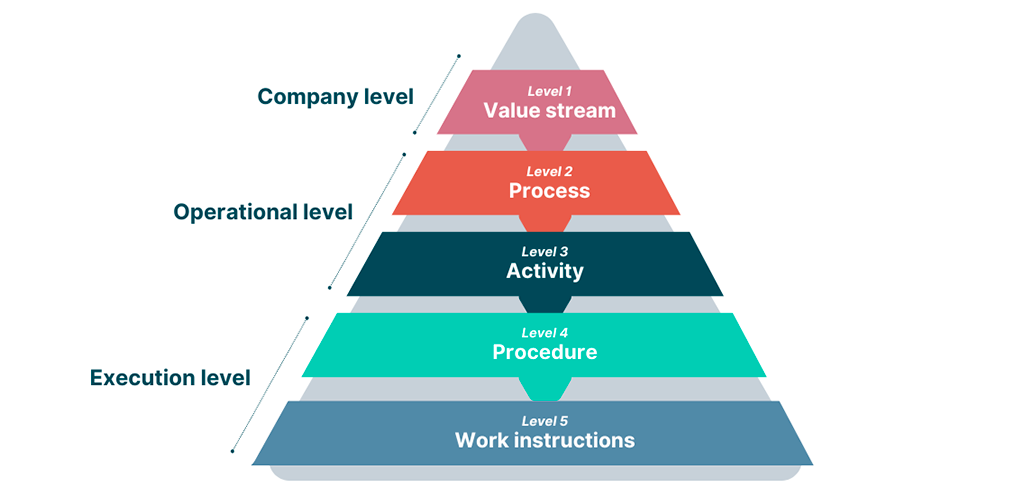

EMS Process Optimization Services

Our EMS Process Optimization Services focus on enhancing your manufacturing efficiency and productivity. We conduct thorough assessments of your existing processes to identify bottlenecks and areas for improvement. By implementing best practices, advanced technologies, and data-driven strategies, we help streamline workflows, reduce cycle times, and minimize waste. Trust us to deliver

tailored solutions that elevate your operational performance and drive continuous improvement in your electronic manufacturing services.

Unlock Excellence with Specialized EMS Training

EMS Training Services

At SB2P Technologies and Solutions, we provide cutting-edge training in SMT and Through-Hole (TH) Technologies to enhance the skills of your team and optimize your electronic manufacturing processes. Our EMS Training Services are designed to equip your workforce with the expertise needed to thrive in the competitive electronics industry.

Our comprehensive, hands-on programs cover:

- SMT Assembly Mastery: Dive deep into component placement, solder paste printing, and advanced reflow soldering techniques.

- Through-Hole Technology Expertise: Learn the ins and outs of manual and automated insertion, wave soldering, and lead forming for reliable assemblies.

- Advanced Quality Control & Inspection: Gain proficiency in state-of-the-art inspection methods to ensure flawless product performance.

- Integrated Manufacturing Solutions: Understand how to seamlessly combine SMT and TH technologies for high-performance, mixed-technology PCBs.

Our expert trainers bring real-world scenarios into the classroom, providing practical knowledge and skills that ensure your team can implement industry best practices. We focus on quality assurance, process optimization, and equipment operation to empower your workforce to deliver superior results.

Let us partner with you to drive operational efficiency, maintain high standards, and accelerate production success in your electronics manufacturing operations.

NPI Consulting and Services

At SB2P Technologies and Solutions, we specialize in NPI (New Product Introduction) Consulting and Services to streamline your transition from design to production. Our services include DFM (Design for Manufacturability), prototype validation, process optimization, and production scaling. We focus on reducing design cycles, optimizing assembly processes, and ensuring seamless integration into high-volume manufacturing. With expertise in supply chain management, quality control, and compliance, we accelerate your product launch while maintaining top-tier standards. Contact us to optimize your NPI process for faster, efficient production.

Empowering Your Team for Excellence

Mastering Quality Standards

we provide comprehensive training and implementation services that empower your team to integrate the highest industry standards into your operations. Our expert-led programs ensure that your staff is fully equipped to implement ISO 9001, ISO 14001, IPC certifications, and other crucial methodologies, ultimately enhancing your organization’s quality management and operational efficiency.

Our Core Training & Implementation Services Include

ISO 9001 Training & Implementation

Develop and implement a robust Quality Management System (QMS) to improve efficiency, meet customer expectations, and comply with international standards.

ISO 14001 Training & Implementation

Implement an Environmental Management System (EMS) to minimize environmental impact, reduce waste, and enhance your organization’s sustainability.

IPC Standards Training

Master IPC-A-610, IPC-2221, and other critical IPC certifications, ensuring your team meets the highest standards of electronic assembly quality, PCB design, and manufacturing processes.

7QC Tools Training

Learn to apply the 7 Quality Control Tools (such as Pareto Analysis, Fishbone Diagrams, Control Charts, and Scatter Diagrams) to identify issues, measure performance, and drive continuous improvement.

Kanban & Lean Manufacturing

Optimize workflow and improve inventory management through Kanban techniques, enhancing production efficiency and reducing lead times.

FMEA (Failure Mode and Effect Analysis)

Learn how to proactively identify potential failure modes in design and manufacturing, assessing risks to enhance product safety and reliability.

8D Analysis

Understand how to leverage 8D Analysis for effective root cause analysis, corrective actions, and permanent solutions, improving product reliability and customer satisfaction.

Statistical Process Control (SPC)

Gain practical skills in using SPC to monitor and control manufacturing processes, ensuring consistent product quality and reducing variation in output.

APQP (Advanced Product Quality Planning)

Implement APQP for proactive quality planning throughout the product lifecycle, from design to manufacturing, ensuring your product meets or exceeds customer expectations.

TPM (Total Productive Maintenance)

Gain insights into TPM principles to maximize equipment uptime, prevent breakdowns, and improve overall equipment effectiveness (OEE).

MSA (Measurement Systems Analysis)

Master techniques to evaluate the accuracy and reliability of measurement systems, ensuring data consistency in decision-making.

PPAP (Production Part Approval Process)

Understand PPAP to ensure that all production parts meet the required specifications before full-scale production.